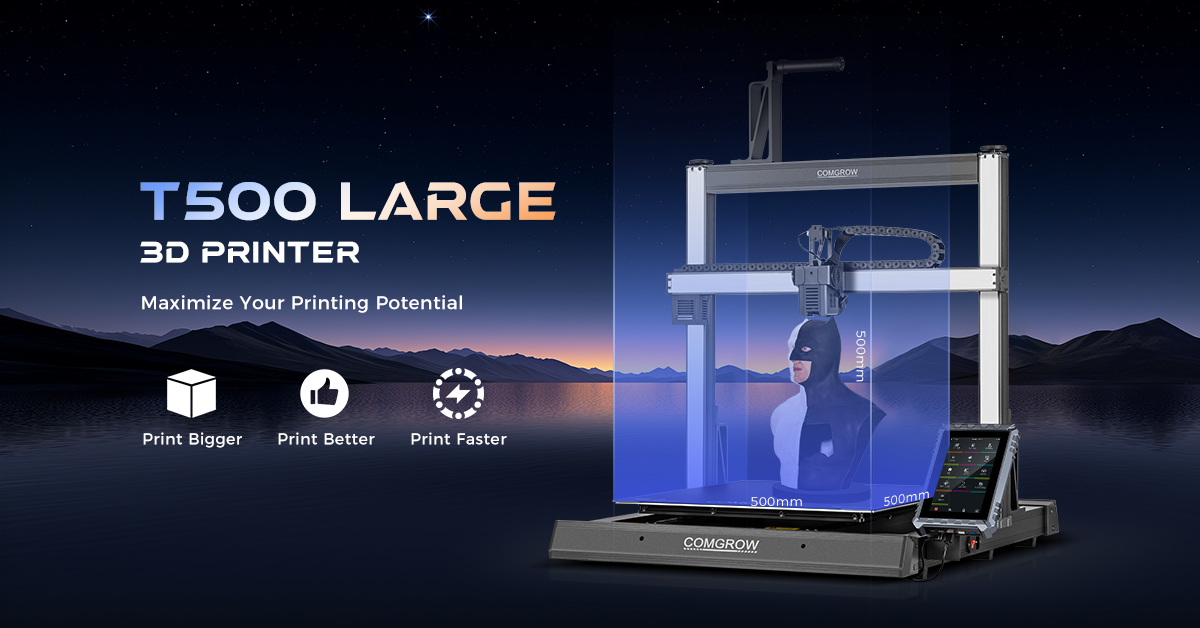

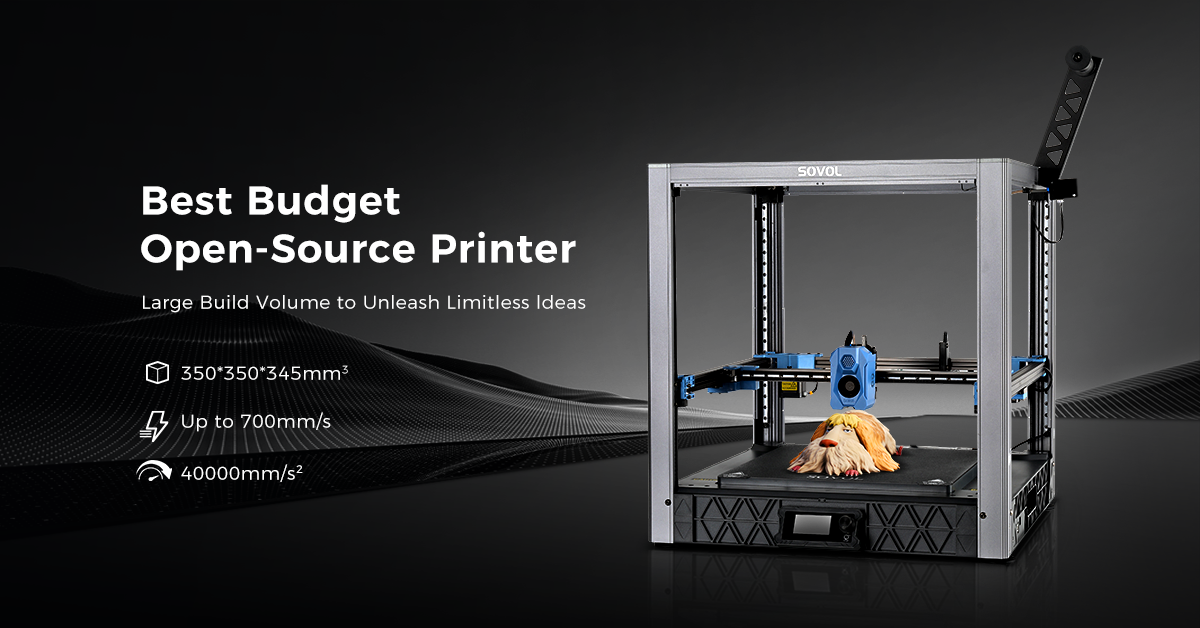

Choosing the right large 3D printer can feel overwhelming, but it doesn’t have to be. Whether you’re diving into 3D printing for big projects or upgrading your setup, knowing what fits your needs makes all the difference. The demand for large-format printers has skyrocketed, with the market expected to grow from $2.5 billion in 2023 to over $12 billion by 2032. This surge proves that more people are turning to solutions like the Sovol SV08 and Comgrow T500 for their creative and manufacturing needs. So, how do you find the perfect printer for your goals? Let’s explore.

Key Takeaways

- Think about your project size and print area needs. Bigger printers can make larger items without joining pieces.

- Check what materials the printer can use. Pick one that works with the materials you need, especially for special filaments.

- Choose a printer based on how you’ll use it. Printing for fun, work, or testing needs different features.

- Look at important details like speed and print quality. A good mix of speed and detail helps printing go smoothly.

- Find a printer with good support and a warranty. Helpful support can save you time and money later.

Identifying Your Needs for a Large 3D Printer

Project Size and Build Volume Requirements

The size of your projects matters when picking a 3D printer. Bigger projects need a printer with a larger build volume. This decides how big your prints can be without breaking them into parts. For instance, a printer with a build volume of 300 x 300 x 400 mm works for medium projects. Larger printers are better for huge prototypes or production pieces.

The 3D printing market is growing fast. In 2023, it reached $22.14 billion, with a 26.8% growth rate. More people want printers for bigger projects. About 70% of users printed more parts in 2023 than in 2022. This shows a move toward larger, complex designs.

Think about the biggest object you want to print. A bigger build volume saves time since you won’t need to join smaller parts. It also makes detailed designs more accurate.

Not all printers work with every material. Some handle basic ones like PLA and ABS. Others can use advanced materials like carbon fiber or Ultem. Your material choice depends on your project. For strong, heat-resistant parts, you’ll need a printer for high-performance materials.

Professional printers support more materials, making them great for industrial tasks. Hobby printers usually work with simpler filaments. If you want to try different materials, pick a printer with a heated bed or enclosed chamber. These features keep temperatures steady, which is key for advanced materials.

Intended Use: Prototyping, Production, or Hobby

How you plan to use your printer will help you decide. Are you testing designs, making products, or just having fun with 3D printing? Each purpose needs different features.

- Prototyping: For testing designs, choose a printer with high detail and accuracy.

- Production: For making products, get a printer with a large build volume and fast speed. Industrial printers are best for this.

- Hobby: For fun, a simple printer is fine. These are good for learning but may lack advanced features.

Professional printers with larger build volumes save time by avoiding model splitting. This also improves print quality. Whether you’re new or experienced, knowing your goals helps you pick the right printer.

Key Specifications in a 3D Printer Buying Guide

Build Volume and Maximum Print Size

The build volume is key when picking a large 3D printer. It decides how big your printed objects can be. If you work on large prototypes or parts, choose a printer with a big build volume.

Here’s a simple table showing important measurements for modern 3D printers:

|

Feature |

Measurement |

|---|---|

|

Build Volume |

|

|

Minimum Layer Height |

50 µm |

|

Printhead Temperature |

500 °C |

|

Buildplate Temperature |

180 °C |

|

Chamber Temperature |

195 °C (active heating) |

|

Filament Diameter |

1.75 mm |

|

Number of Printheads |

2 (with purging system) |

|

Printing Speed |

Up to 400 mm/s |

A bigger build volume lets you print large items in one go. This saves time and makes prints more accurate. For example, a printer with a build volume of 380 x 380 x 420 mm works well for most creative or industrial tasks. Think about the size of your usual projects and match it to the printer’s build volume to avoid limits.

Print Resolution and Quality Standards

Print resolution affects how detailed your 3D prints are. It’s measured in microns (µm) and shows how fine the details can be. Lower numbers mean smoother surfaces and better details. For example, a 50 µm layer height is great for detailed designs or professional models.

Ask yourself these questions about resolution:

- Do your projects need fine details?

- Are smooth surfaces important?

If yes, pick a printer with adjustable resolution settings. This lets you switch between detailed prints and faster, simpler ones. Keep in mind, higher resolution often means slower printing. Balance your need for speed and quality.

Print Speed and Workflow Efficiency

Print speed shows how fast your printer can finish a project. Faster printers are helpful, especially for industries where time matters. But speed isn’t just about movement—it’s also about how well the printer manages the process.

Here are some things to think about:

- Throughput: How many prints can it finish in a set time?

- Capacity Utilization: Is the printer being used to its full potential?

- Flow Efficiency: How much time adds value to the final print?

Industries like aerospace and healthcare benefit from faster 3D printing. Aerospace companies make lighter parts that save fuel. Healthcare uses it for custom implants, helping patients faster. These examples show how speed and quality improve results.

Choose a printer that balances speed and detail. A model printing up to 400 mm/s can handle both detailed designs and large projects.

Evaluating Features and Material Compatibility

Material Choices and Filament Types

The materials your printer uses are very important. Different filaments have special uses, so knowing them helps you choose wisely.

Here’s a simple list of common filament types:

- Standard Filaments: PLA, ABS, PETG, Tough PLA, ASA, Nylon

- Flexible Filaments: TPU

- Composite Filaments: Carbon Fiber, Metal

- Specialty Filaments: Polycarbonate, PC-ABS, Polypropylene

- Support Filaments: PVA, Breakaway Support, HIPS

For strong parts, composite filaments like carbon fiber work best. TPU is great for bendable designs. Specialty filaments like polycarbonate are perfect for tough jobs. Picking the right material for your printer improves your results.

Why Heated Beds and Enclosures Matter

Heated beds and enclosures aren’t just extras—they improve prints a lot. They keep temperatures steady, stop warping, and help layers stick better.

|

Benefit |

What It Does |

|---|---|

|

Temperature Control |

Enclosures keep the temperature steady, which helps certain materials print better. |

|

Stops Warping |

Enclosures block drafts, reducing warping or layers pulling apart during printing. |

|

Works in Cold Rooms |

Helps prints look better in rooms colder than 20°C. |

If you use ABS or nylon, heated beds and enclosures are must-haves. These features make prints smoother and stronger, even in tough conditions.

Software and Connection Features

Your printer’s software and connections make printing easier. Look for printers that work with slicing software like Cura or PrusaSlicer. These tools let you adjust settings for better prints.

Connection options are also important. Wi-Fi printers let you send files from your computer or phone. USB and SD card slots are good for offline printing. Some printers even allow cloud printing, so you can manage projects from anywhere.

Think about how you’ll use your printer every day. A printer with good software and connection options saves time and makes printing easier.

Budgeting for a Large 3D Printer

Balancing Price with Features and Value

When buying a large 3D printer, balance cost with features. Avoid paying for features you won’t use. But don’t skip important ones either. Focus on what your projects need most. This could be print size, material options, or special features like dual extruders.

Here’s a simple price comparison for different models:

|

3D Printer Model |

Price Range |

|---|---|

|

EVO 2X |

$12,995.00 – $16,495.00 |

|

EVO 22 |

$8,959.30 |

|

EVO Additive Manufacturing Center |

$5,949.30 |

|

EVO R |

$5,499.00 |

|

AXIOM 20 |

$8,995.00 – $9,995.00 |

|

AXIOM DUAL |

$5,499.00 |

|

AXIOMe |

$3,399.00 |

|

$549.00-599.00 |

|

|

$799.00 |

Prices depend on the printer’s features. Beginners might prefer cheaper models. Professionals may need high-end printers for better results. Spending more upfront can save time and money later.

Chair printed by Morley Kert using SV08

Comparing Entry-Level and High-End Models

Entry-level printers are good for beginners or hobbies. They cost less and are easy to use. But they may lack advanced features like bigger print sizes or faster speeds. High-end printers offer more. They print faster, handle bigger projects, and work with more materials.

Ask yourself:

- Do you need a printer for simple or complex tasks?

- Is it for fun or professional use?

For big projects, a high-end printer is worth it. It offers larger print sizes and faster work. But for small experiments, an entry-level printer works fine without costing too much.

Accounting for Maintenance and Consumable Costs

The cost of a 3D printer isn’t just the price tag. You also need to think about maintenance and supplies. These include filament, repairs, and labor costs if used for business.

Here’s a breakdown of common costs:

|

Cost Component |

Example Value |

|---|---|

|

Material Cost per Hour |

$0.50 |

|

Wear and Tear Cost per Hour |

$0.50 |

|

Labor Cost per Hour |

$20 |

|

Amortization Cost per Hour |

$0.40 |

|

Indirect Costs per Hour |

$2 |

|

Total Hourly Cost |

$23.42 |

These costs can grow, especially for big projects. To save money, pick a printer that’s efficient and durable. Choose models with strong parts and good support to avoid extra expenses.

Support and Community Resources for Choosing a 3D Printer

Why Customer Service and Warranty Matter

When buying a large 3D printer, good support is key. A warranty protects your money by covering repairs or replacements. Helpful customer service solves problems fast, keeping your projects moving.

Manufacturers check and test printers before sending them to you. This ensures the printer works well and reduces defects. Here’s why these features are important:

|

Feature |

Benefit |

|---|---|

|

Inspection and Testing |

Makes sure the printer meets quality standards. |

|

Active Defect Detection |

|

|

Customer Support Accessibility |

Fixes problems quickly, saving time and effort. |

Before buying, read the warranty details and customer reviews. These can save you money and trouble later.

Using Online Groups for Help

Online groups are great for learning about 3D printing. Websites like Reddit and Facebook have communities of users. You can ask questions, share ideas, and get advice.

Here’s why these groups are useful:

- 61.5% of users say quick feedback helps fix problems faster.

- Sharing pictures of bad prints helps find solutions easily.

- Beginners learn new tips and terms from these groups.

Some people get annoyed by slow replies or unhelpful members. To benefit more, stay active and help others too. Working together makes 3D printing more fun and easier.

Finding Tutorials and Fix-It Guides

Learning to use your 3D printer is easier with tutorials. Many companies provide videos and guides to help you. These explain how to set up and fix your printer step by step.

YouTube and blogs also have helpful tips and tricks. They teach you how to improve prints and try advanced methods. Save a few trusted sites for quick help when needed.

Pick a printer with good support and resources. This ensures you’ll always have help, whether you’re new or experienced.

Picking the best large 3D printer is simple. Focus on size, materials, and features like speed and accuracy. A strong and durable printer gives better prints and lasts longer.

Here’s a quick list of key tips for buying a 3D printer:

|

Factor |

What It Means |

|---|---|

|

Print Speed |

Faster printing saves time and lowers costs. |

|

Dual Extruder Systems |

Lets you use support materials, making designs easier and cheaper. |

|

Reliability |

Important for lasting use, giving fewer errors and less downtime. |

|

Precision |

Needed for exact details, especially in manufacturing. |

|

Repeatability |

Makes sure prints stay the same quality every time. |

|

Operator Safety |

Filters and covers keep users safe from harmful fumes. |

|

Material Compatibility |

Lets the printer work with many types of plastics for different projects. |

Good options include the Sovol SV08 and Comgrow T500. These printers are strong, reliable, and packed with useful features. Also, join online groups and watch tutorials for help. They’re great for fixing problems and learning new tricks.

With the right printer and support, you can turn your ideas into reality!

FAQ

What makes a large 3D printer special?

Large 3D printers can print bigger objects at once. They also work better with advanced materials, making them great for professional jobs.

How can I make my 3D prints look better?

Adjust settings like layer height and temperature. Use good-quality filaments and keep the printer bed level. Heated beds and enclosures help stop warping and improve details.

What materials are best for big 3D printing projects?

For strong prints, use ABS, nylon, or carbon fiber. TPU is good for flexible designs. Polycarbonate works well for tough tasks.

How do I pick the right 3D printer?

Think about your project size and materials. If you need speed and accuracy, choose a printer with dual extruders and a large build volume. Match the printer to your goals.

Are large 3D printers hard to take care of?

No, they’re not. Clean them often and store filaments properly. Check parts like nozzles and belts for damage. Many printers include guides to help with maintenance.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.